About Us

Airframe & Recovery

Team Description

The Airframe, Integration, and Recovery team is responsible for the rocket’s safe descent back to the ground, the structure and bodywork of the rocket, and the integration of the recovery system, avionics, propulsion systems and payload. All of this must be achieved whilst maintaining structural integrity, precision alignment and aerodynamic form. This requires the design, simulation, manufacture and test of both metal and composite parts, all done by our talented students. Design is done using Fusion360, whilst FEA simulations are mainly done using Abaqus. The team prides itself in carrying out manufacturing of composite parts in-house, such as the nosecone, fincan, structural body-tubes, and panels. The team also hosts unique parachute reefing tests at the historic Lasham Airfield and compressive tests of metal 3D printed parts at Imperial’s DFF Laboratory.

Our projects this year include:

- Composite filament winding machine

- Forged carbon fibre and prepreg composites

- Retractable launch lugs

- Evolved seperation system

Electronics

Team Description

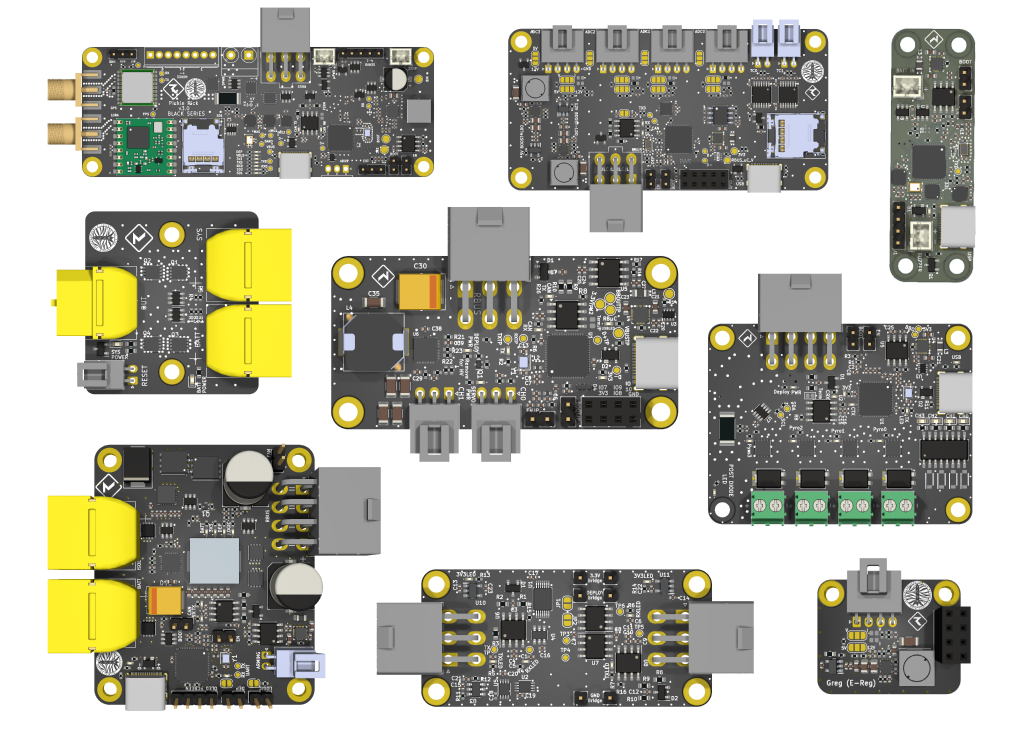

The electronics team is responsible for engineering the entire avionics stack. This ranges over a wide range of technologies, from our custom flight PCBs and firmwares, to a backend stack that provides the operations teams with full telemetry readouts and control over rocket sub-systems.

The frameworks and technologies we use include C++ running on FreeRTOS for our firmware and custom ESP32 boards using an arbitrated CAN bus for communication that handles everything from actuator control to reading pressure sensors, and calculating the position of the rocket. Our backend applications are built in Python to enable platform agnostic development. These apps enable USB access onto the CAN bus, as well as hosting a telemetry dashboard through Grafana that shows live data from the flight vehicle.

Our main projects this year include:

- Conformal Antennas

- Buck-Boost Regulator

- Camera Controller

- Firmware

- Design and scoping of a new avionics stack

- Thrust vectoring Guidance, Navigation and Control

Propulsion

Team Description

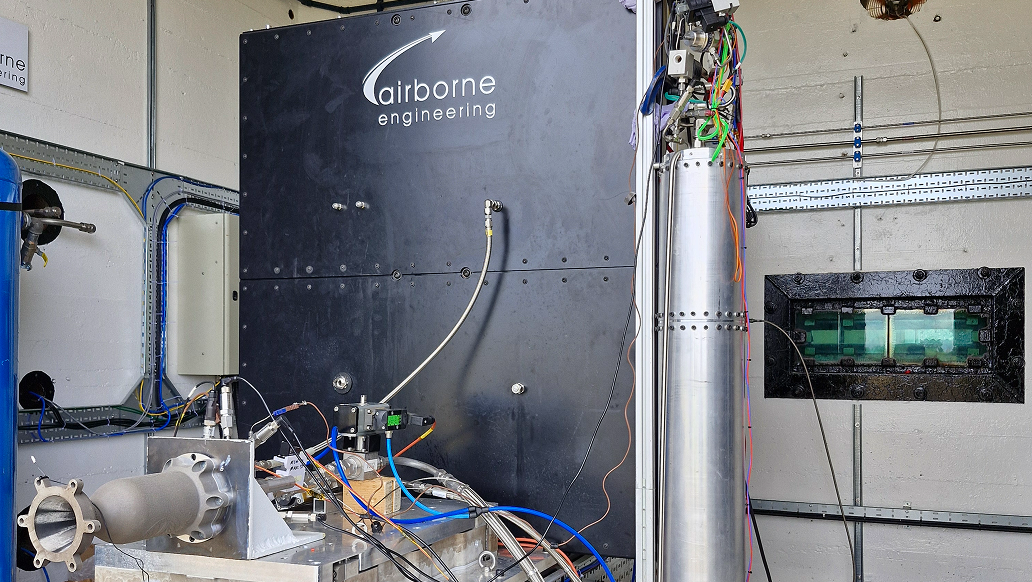

The propulsion team are responsible for the design, development, and testing of various propulsion related subsystems. These include the design of engines, tanks, and rocket/ground station feed systems, as well as operation of ICLR’s Silwood Park test site.

The team operates primarily on pressure fed, liquid bipropellant propulsion cycles. Our design work involves performance modelling using designated engine simulation software, structural simulations with FEA applications, and a large amount of CAD. Alongside this, a big part of our job is testing of propulsion systems, whether that be small bench tests, pressure tests, or hotfire engine tests.

Our projects this year include:

- Custom COPV tanks

- Overhauled flight vehicle feed system

- Redesigned pressure and mass flow controllers

- Permanent high-thrust test stand with a dedicated propellant delivery system

Flight Dynamics

Team Description

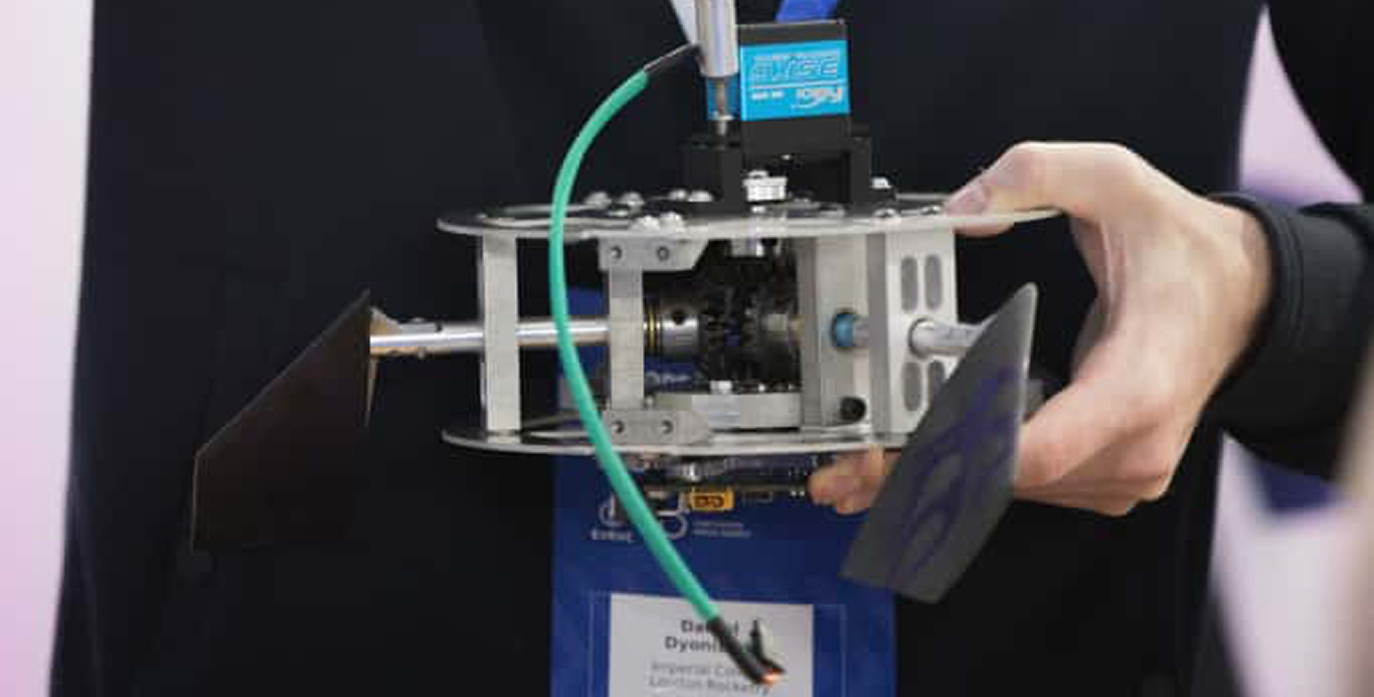

The flight dynamics team works on everything about the trajectory of the rocket. Our main work is to provide flight simulations (or develop tools ourselves) and use them to design any aerodynamic parts such as fins. We also work on control systems for hopper vehicles, or in the past, canards on the main rocket. Our main goal is to integrate our in-house simulator with the rocket’s hardware to enable hardware-in-the-loop testing, a unique capability among student rocketry teams.

Our projects this year include:

- Hardware-in-the-Loop

- Grid fin demonstration

- EuRoC ‘26 flight simulation

Payload

Our projects this year include:

- EuRoC ‘26 payload

- Mini-Hathor deployable heatshield